The company was founded in 1954, we boast considerable experience and a lot of passion in the processing and molding of plastic materials. We are constantly evolving to keep up with the most innovative machine processing systems and of the company management. Passion and seriousness see us committed to satisfying every need and expectation of our customers.

We are committed, structured, and organized to provide customized solutions for the client. We work in co-design with Large OEM’s to reach the best possible final configuration of the product.

We specialize in the molding of small technical and aesthetic details, for various product sectors listed later. We have a molding department made up of 14 injection presses, one of which is vertical, all of the latest generation, as well as areas equipped for assembly of components and for the refurbishment of the moulds.

We are equipped to compose the finished product by assembling all its components and be a full system supplier.

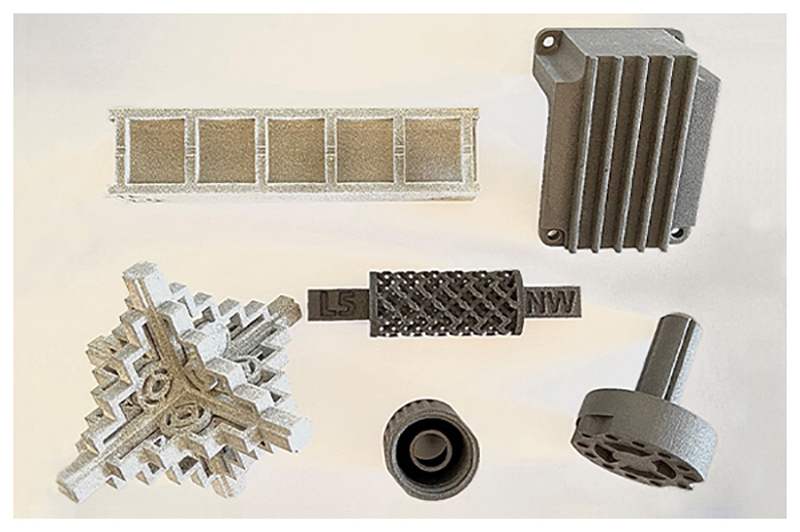

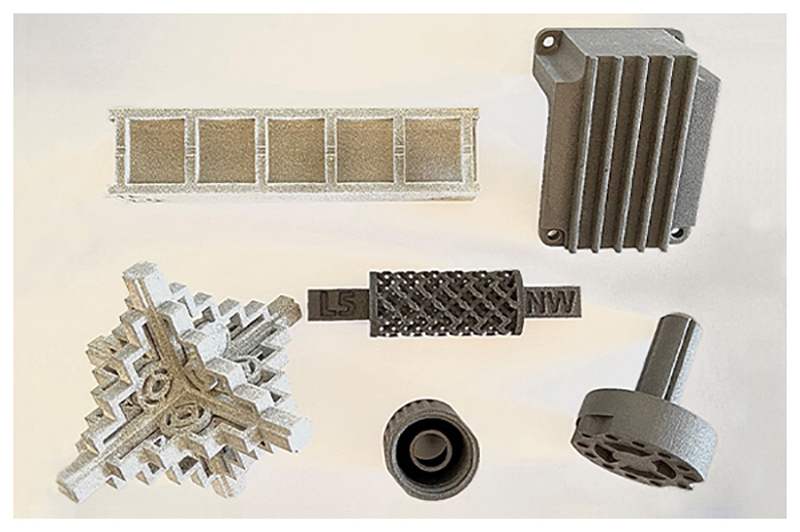

We offer the ideal solution for prototypes and production batches that exceed even 5,000 pcs, depending on their size. This possibility avoids the initial investment in molds, resulting in a faster production, high quality, and lower risks.

We specialize in the molding of small technical and aesthetic details, for various product sectors listed later. We have a molding department made up of 14 injection presses, one of which is vertical, all of the latest generation, as well as areas equipped for assembly of components and for the refurbishment of the moulds.

We are equipped to compose the finished product by assembling all its components and be a full system supplier.

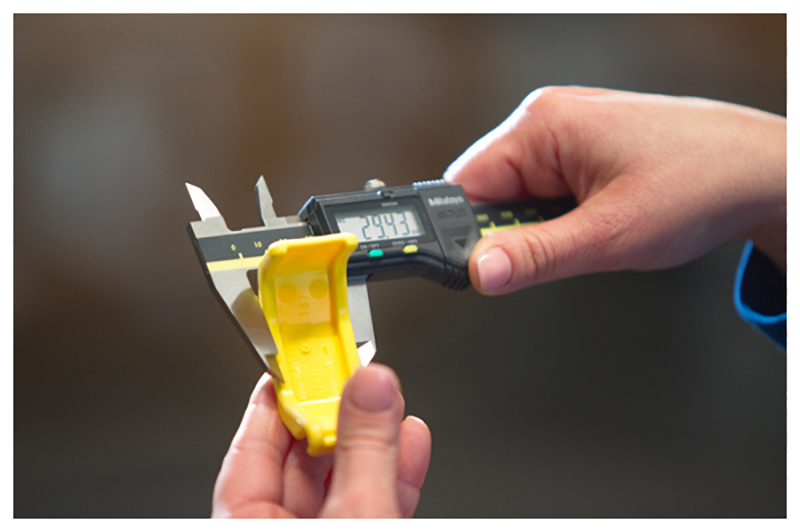

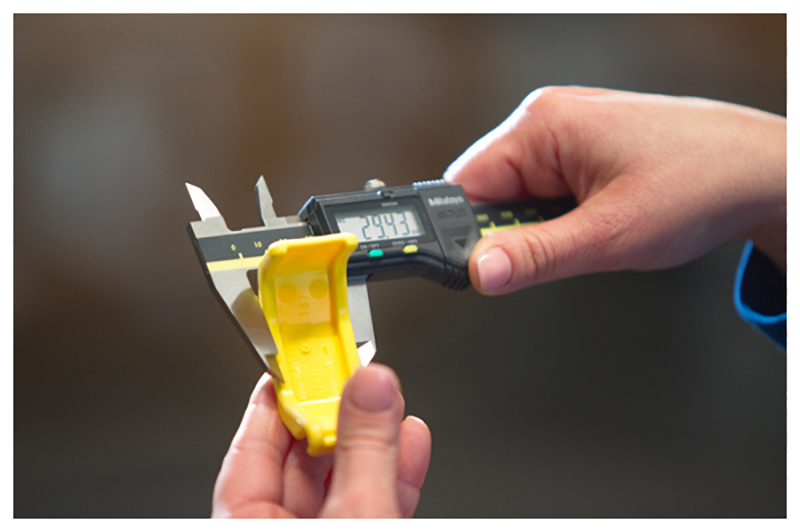

We have been ISO 9001: 2015 certified for almost thirty years. For the customers who require APQP, we are able to submit it in the most complete form. Our investments are aimed at the realisation of stable and reliable production processes according to the guidelines of Lean Manufacturing, and to the permanent training of our workforce.

We offer the ideal solution for prototypes and production batches that exceed even 5,000 pcs, depending on their size. This possibility avoids the initial investment in molds, resulting in a faster production, high quality, and lower risks.

Components for resistors

Connectors

Thermostats and busbars

Insulators for connectors

Connectors for control units

Nuts

Fastners

Spray heads

Clamps

Track components

Technical accessories

Interior curtain systems

Keys

Clutches

Gears

Clips

Tip containers

Machinery accessories

Electromedical

Components for resistors

Connectors

Thermostats and busbars

Insulators for connectors

Connectors for control units

Nuts

Fastners

Spray heads

Clamps

Track components

Technical accessories

Interior curtain systems

Keys

Clutches

Gears

Clips

Tip containers

Machinery accessories

Electromedical

Our constant commitment is to reduce the impact on the environment, paying constant attention to the utmost disposal of production waste. The main goal is to reach 100% of electricity self produced with our own capacity. We aim at the reduction of the consumption of natural resources by limiting the purchase of electric energy: most of the electricity employed is self-produced with our photovoltaic system. With our good knowhow of the supply chain we use clean energy avoiding any waste.